Paper on off-design operation of ACCs presented by University of Seville at ASME Turbo Expo, Boston (USA)

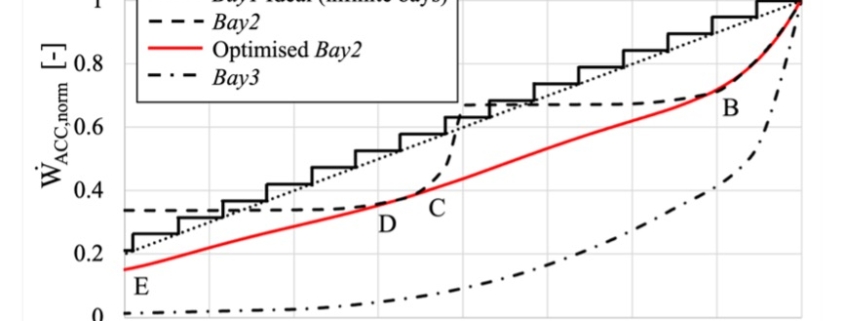

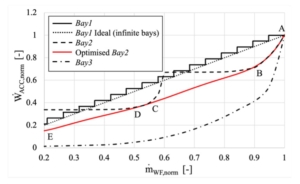

Fan power consumption at reduced mass flow rate for different ACC designs

The researchers at University of Seville have presented their work assessing the part-load operation of supercritical power cycles running on Carbon Dioxide mixtures. As a continuation of the work presented at the 5th European Conference on Supercritical Carbon Dioxide Energy Systems, where the methodology to design ACCs for supercritical CO2 power cycles developed at University of Seville was presented, this paper explores the operation of the cycle when running in off-design. Emphasis is placed on the operation of the ACC because of the strong impact that a wrong operation of this component has on overall cycle performance.

The paper can be downloaded free of charge from the conference website (link). Check the abstract below:

This manuscript, developed in the framework of SCARABEUS project, presents an assessment of the part-load performance of a transcritical Recompression cycle running on a 80%CO2-20%SO2 mixture under different load-control schemes.

The first part of the paper describes the computational platform of the integrated system, implemented in Thermoflex but with profuse use of in-house scripts, in order to accurately describe the off-design performance of key components when operating on CO2 mixtures with non-ideal gas behaviour. These off-design models make use of performance maps for turbomachinery — provided by the SCARABEUS partners — whereas the Conductance Ratio Method employed to model the counter-current heat exchangers is calibrated with in-house tools. The paper is specifically focused on the Heat Rejection Unit, for which a specific design tool accounting for accurate heat transfer between working fluid and cooling medium (air) and for auxiliary power consumption — both in off-design — has been developed by the authors.

In the second part of the paper, different operating strategies of the power cycle are considered, based on keeping one of the following three parameters constant: turbine inlet temperature, turbine outlet temperature or return temperature of molten salts. Globally, plant operation is constrained by the need to keep the temperature of cold HTF returning to the storage system as close as possible to its rated (design) value and by the need to keep turbine outlet temperature below 450°C to avoid the installation of an external cooling system in the low pressure section of this equipment. Therefore, the trade-off between these two parameters and system net efficiency are assessed in the paper. Regarding the Air-Cooled Condenser, the optimal operation strategy of this component found to be based on a combination of Single-speed and Variable Frequency Driver fans.

The results show that the operation at constant turbine inlet temperature leads to the highest net efficiency of the power block, closely followed by the control scheme based on constant return temperature of the heat transfer fluid. Nevertheless, this latter option enables a perfect control on the other two figures of merit. As a consequence, the identification of the best operation strategy must be addressed in future works by means of a thorough techno-economic assessment considering the annual yield of the plant.