Paper on energy losses in radial turbines presented by City, University of London at ASME Turbo Expo, Boston (USA)

Fan power consumption at reduced mass flow rate for different ACC designs

The researchers at City, University of London have presented their work assessing the different contributions to energy losses experienced by radial turbines working with Carbon Dioxide mixtures in supercritical power cycles. This research work also considers the effect of turbine scale on the breakdown of energy losses, assessing this for turbines in cycles rated at 0.1 MWe, 1 MWe and 10 MWe. The work makes use of meanline design codes and CFD analysis to assess the impact of fluid composition and scale and to compare the data obtained against data from literature.

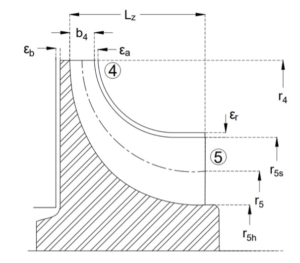

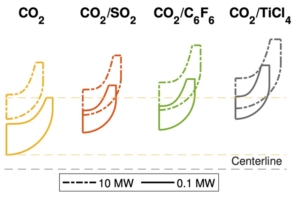

Meridional profile of radial inflow turbines working with different Carbon Dioxide mixtures and with different scales (plots are not to scale)

The paper can be downloaded free of charge from the conference website (link). Check the abstract below:

Recent studies have indicated the potential of CO2-mixtures to lower the cost of concentrated solar power plants. Based on aerodynamic and cost considerations, radial inflow turbines (RIT) can be a suitable choice for small to medium sized sCO2 power plants (about 100 kW to 10 MW). The aim of this paper is to quantify the effect of doping CO2 on the design of RITs. This is achieved by comparing the 1D mean-line designs and aerodynamic losses of pure sCO2 RITs with those of three sCO2 mixtures containing tetrachloride (TiCl4), sulphur dioxide (SO2), and hexaflourobenzene (C6F6).

Results show that the optimal turbine designs for all working fluids will have similar rotor shapes and velocity diagrams. However, factors such as the clearance-to-blade-height ratio, turbine pressure ratio, and the difference in the viscosity of the fluids cause variations in the achievable turbine efficiency. Once the effects of these factors are eliminated, differences in the total-to-static efficiency amongst the fluids may become less than 0.1%. Moreover, if rotational speed limits are imposed, then greater differences in the designs and efficiencies of the turbines emerge amongst the fluids. It was found that limiting the rotational speed reduces the total-to-static efficiency in all fluids; the maximum reduction is about 15% in 0.1 MW CO2 compared to the 3% reduction in CO2/TiCl4 turbines of the same power.

Among the mixtures studied, CO2/TiCl4 achieved the highest performance, followed by CO2/C6F6, and then CO2/SO2. For example, 100 kW turbines for CO2/TiCl4, CO2/C6F6, CO2/SO2, and CO2 achieve total-to-static efficiencies of 80.0%, 77.4%, 78.1%, and 75.5% respectively. Whereas, the efficiencies for 10 MW turbines are 87.8%, 87.3%, 87.5%, and 87.2%, in the same order. differences in the designs and efficiencies of the turbines emerge