Recuperator Model with design process using pure CO2

The SCARABEUS concept relies on a recuperative cycle using supercritical carbon dioxide as working fluid. Being supercritical and in order to achieve high efficiency, very high pressures and temperatures are involved and a recuperator becomes mandatory. This is a device which can improve the thermodynamic cycle efficiency by cooling the sCO2 after its expansion and heating it after its compression, without any additional heat exchange with the environment.

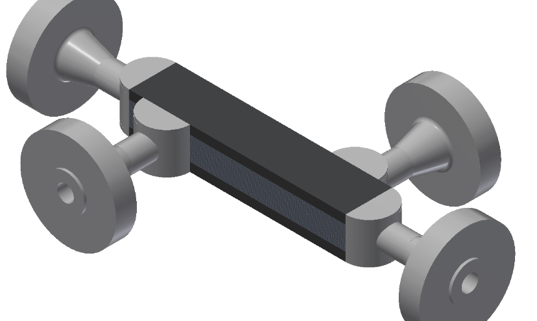

3D model of the recuperator to be installed in the test rig at TUW

The advantage to use printed circuit heat exchanger technology in the recuperator is to withstand high pressure and high temperature with reduced footprint (large area-to-volume ratio). This is why PCHE is the technology of choice in SCARABEUS. The 3D model above represents the recuperator which will be installed in the test rig at TUW. It is designed for a pressure of 220 bar and a temperature of 650°C and the geometry of the internal channel configuration is shown below.

Internal channels of the PCHE developed by KELVION for SCARABEUS

Some CFD calculations will be performed to study new types of internal geometries in order to optimize the thermal-hydraulical performances and to decrease heat exchange area. While this technology is already very compact, the Company is pursuing further reductions of footprint.